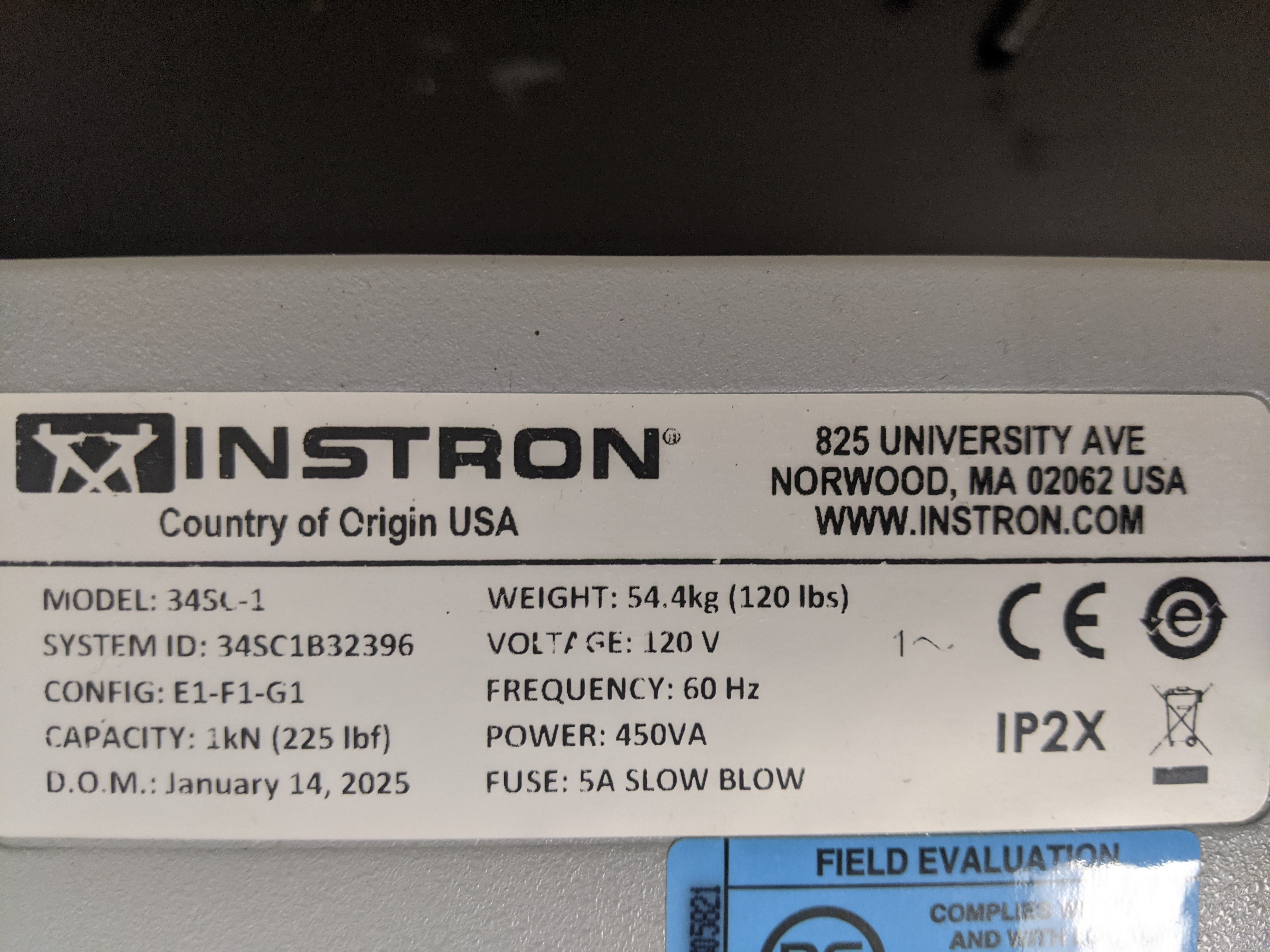

Instron 34SC-1 Universal Testing System

Description

The Instron 34SC-1 Universal Testing System is a single-column, electromechanical testing machine designed for low-force mechanical testing applications, offering precision, reliability, and versatility. Part of Instron’s 3400 Series, it has a force capacity of up to 1 kN (1000 N or approximately 225 lbf), making it ideal for tensile, compression, flexure, peel, puncture, friction, and shear tests on a wide range of materials, including plastics, textiles, biomaterials, thin films, and small components.

The 34SC-1 is equipped with a 1000 N load cell, a 1000 N crosshead, and a 1000 N pneumatic side-action grip, and is controlled by Instron’s Bluehill Universal software, which allows for easy test setup, data acquisition, and analysis. The system is also equipped with a video extensometer for non-contact strain measurement, and a temperature chamber for testing at controlled temperatures.

Technical Details

| Specification | Details |

|---|---|

| Model | Instron 34SC-1 (3400 Series, Single Column) |

| Force Capacity | 1 kN (1000 N, ~225 lbf) |

| Load Accuracy | ±0.5% of reading down to 1/500th of load cell capacity (±1% below 1/500) |

| Load Cell Compatibility | Instron Smart Load Cells (e.g., 5 N to 1 kN range) |

| Crosshead Travel (Standard) | ~675 mm (26.6 in) |

| Crosshead Travel (Extra Height) | ~975 mm (38.4 in) |

| Maximum Speed | 1000 mm/min (40 in/min) |

| Minimum Speed | 0.001 mm/min (0.00004 in/min) |

| Speed Accuracy | ±0.1% of set speed under load |

| Return Speed | Up to 2000 mm/min (80 in/min) |

| Vertical Test Space (Standard) | ~772 mm (30.4 in) from base to crosshead |

| Vertical Test Space (Extra Height) | ~1072 mm (42.2 in) |

| Horizontal Test Space | 100 mm (3.94 in) throat depth |

| Data Acquisition Rate | Up to 1 kHz (1000 data points per second) |

| Drive System | Brushless AC servomotor, pre-loaded ball screws |

| Position Control Resolution | <0.001 mm (0.00004 in) |

| Power Requirements | 100-240 VAC, 50/60 Hz, single phase, 400 VA max |

| Operating Temperature | +10°C to +38°C (+50°F to +100°F) |

| Storage Temperature | -40°C to +66°C (-40°F to +150°F) |

| Humidity Range | 10% to 90% non-condensing |

| Height (Standard) | 1048 mm (41.3 in) |

| Height (Extra Height) | 1348 mm (53.1 in) |

| Width | 575 mm (22.6 in) |

| Depth | 608 mm (23.9 in) |

| Weight | ~65 kg (143 lb) |

| Software | Bluehill Universal (touchscreen or PC interface) |

| Safety Features | Operator Protect (status-aware operation), emergency stop, limit switches |

| Standards Compliance | Supports ASTM, ISO, EN, JIS, and custom test methods |

| Accessory Compatibility | Grips, fixtures, extensometers (contact Instron for catalog) |

| Frame Stiffness | ~1.2 kN/mm (nominal, varies with setup) |

| Noise Level | <70 dB during operation |